What is a business energy storage system (ESS/BESS) and how does it work?

What is an ESS/BESS? Learn how a business energy storage system works, its components, and applications like peak shaving and dynamic pricing.

What is a business energy storage system (ESS/BESS) and how does it work?

A business energy storage system (also called ESS or BESS) is an on-site battery system that stores electricity (from your solar PV or from the grid) and uses it later to cut energy costs, reduce peaks, and improve reliability. This guide is for business owners, facility managers, and energy managers who are new to commercial battery storage and want a clear, practical explanation without engineering jargon. You’ll learn what ESS/BESS means, what the key components do (battery, PCS, BMS, EMS), and how companies use storage for peak shaving, PV self-consumption, and dynamic pricing.

What is an ESS/BESS?

An ESS (Energy Storage System) is a broad term for any technology that stores energy. In practice, in commercial settings, ESS usually means a battery-based system.

A BESS (Battery Energy Storage System) is a more specific term: it is an ESS where the storage medium is a battery (most often lithium-ion). Many articles use ESS and BESS interchangeably, and you’ll see both terms in quotes, tenders, and installer proposals.

What makes a business (commercial/industrial) ESS different from a “home battery” is scale and purpose:

- It’s sized for business loads (often tens to hundreds of kW and kWh; sometimes much larger).

- It targets bill drivers that matter for companies: peak demand charges, time-of-use/dynamic pricing, PV curtailment, and operational continuity.

- It includes industrial-grade power electronics, protection, monitoring, and control software (PCS + EMS + BMS) to run safely and predictably (EPRI, Vertiv).

How does a BESS work?

A BESS works by moving electricity through three stages—charge → store → discharge—while a control layer continuously decides when to do each step.

1) Charging (getting energy into the battery)

The system charges the battery from:

- Solar PV (store midday surplus instead of exporting it immediately)

- The grid (buy electricity when it’s cheaper and store it)

A bidirectional converter (PCS) handles the power flow and converts AC↔DC as needed (EnergyToolbase, Power-Sonic).

2) Storage (keeping energy safely)

Inside the battery, electrical energy becomes chemical energy. During storage, the battery management system (BMS) keeps the battery within safe operating limits—especially temperature, voltage, and state of charge (EcoFlow, Vertiv).

3) Discharging (using the stored energy)

When your building needs extra power—or electricity prices spike—the PCS converts stored DC energy back into AC power and supplies it to your facility or to the grid (depending on your setup and local rules) (EPRI).

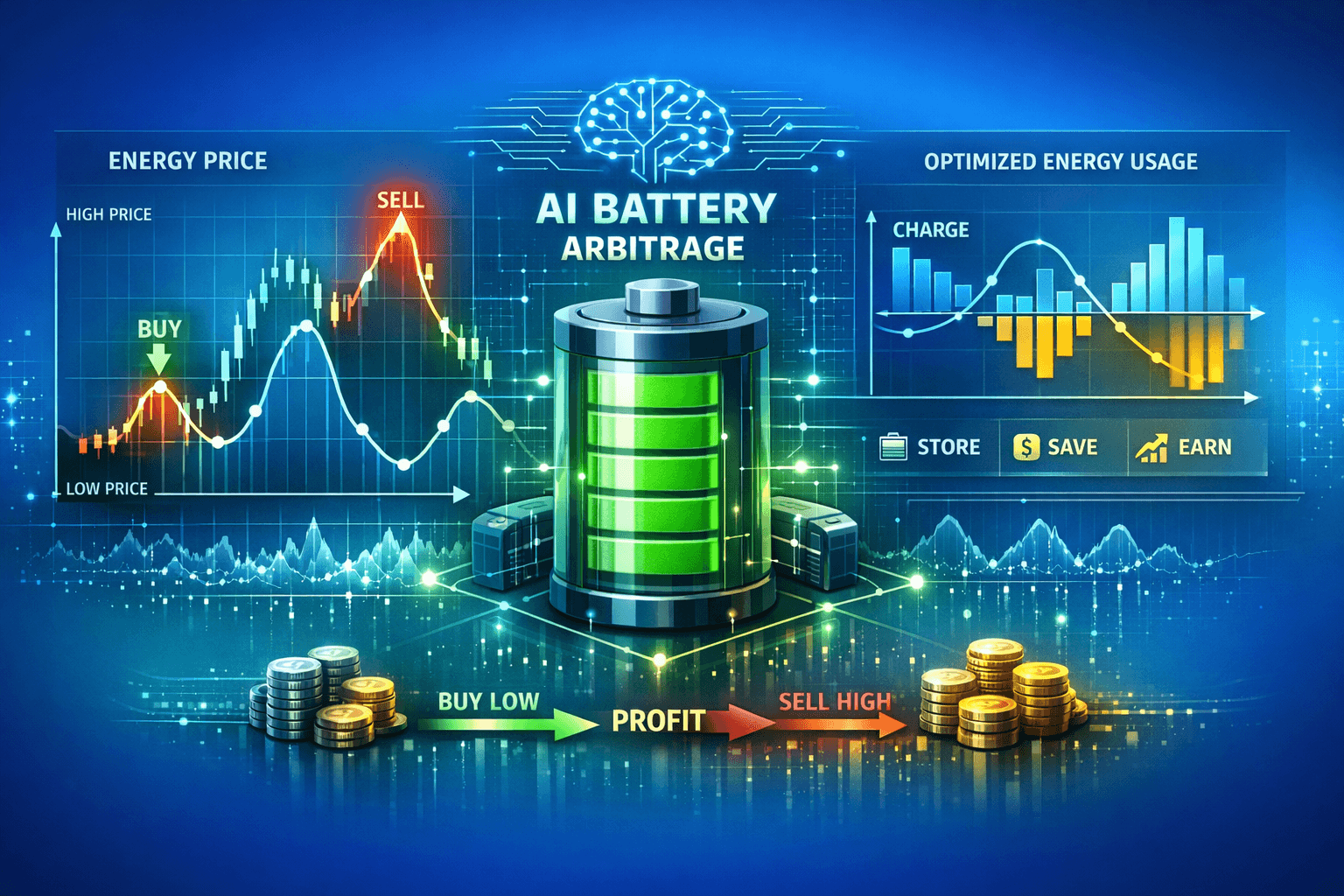

4) Optimization loop (the “smart” part)

In commercial projects, the value isn’t only the battery—it’s how you control it. An EMS (Energy Management System) coordinates charging and discharging using:

- your facility load (real-time and historical)

- PV production

- tariff signals (time-of-use or dynamic pricing)

- constraints that protect the battery (degradation-aware control)

This is where AI-driven optimization can make a meaningful difference: it improves savings by reacting to changes, forecasting, and avoiding “naive cycling” that may reduce battery life.

At AIESS, our goal is simple: 100% automatic, easy-to-implement battery storage that optimizes for fast ROI—without requiring your team to become energy market experts.

Core components of a business energy storage system (ESS/BESS)

A commercial battery storage system is a combination of hardware + software. The names vary by vendor, but the roles are consistent across the industry.

Battery (cells → modules → racks)

The battery is built in levels:

- Cells: the smallest electrochemical units

- Modules: groups of cells packaged together

- Racks / trays: multiple modules connected to reach the required voltage and capacity

For businesses, lithium-ion chemistry is most common because of energy density and lifetime characteristics, and because supply chains are mature. Industry overviews consistently describe the battery as the foundational block of ESS/BESS architectures (EnergyToolbase, EcoFlow).

What you should ask about (in business terms):

- Usable capacity (kWh): how much energy you can actually use

- Power rating (kW): how much instantaneous load it can support

- Cycle life and warranty terms: how the project performs financially over time

BMS (Battery Management System)

The BMS monitors and protects the battery at cell/module level. It typically:

- balances cells (so one weak cell doesn’t limit the entire pack)

- monitors voltage, current, and temperature

- prevents unsafe operation (overcharge/overdischarge/overtemperature)

In short: BMS = battery safety + longevity (EcoFlow, Power-Sonic).

PCS (Power Conversion System) / bidirectional inverter

The PCS is the system that converts power between:

- AC (grid/building power)

- DC (battery power)

Because it is bidirectional, it supports both charging and discharging. The PCS is also where efficiency and grid-interaction behaviors come from (how smoothly it responds, power quality, protection coordination). Many references list PCS as a primary ESS component alongside batteries and controls (EPRI, EnergyToolbase).

EMS (Energy Management System)

The EMS is the “brain” that decides:

- when to charge

- when to discharge

- how much power to move

- which strategy to prioritize (peak shaving vs PV self-consumption vs dynamic pricing)

A modern EMS uses metering data and forecasts to reduce bills while staying within battery constraints (a common theme in commercial ESS education materials) (c3controls, Vertiv).

Supporting equipment (the “silent essentials”)

Commercial systems also include:

- Thermal management (cooling/heating) to keep the battery safe and consistent

- Switchgear and protection (disconnects, breakers, fuses)

- Transformer (in many C&I and utility-scale designs)

- Monitoring and communications (SCADA/portal)

EPRI’s overview lists system components beyond the battery itself, including PCS, transformer, switchgear, and monitoring/control (EPRI).

A simple diagram: how the energy flows

Think of a business BESS as a controlled “buffer” between the grid/PV and your facility loads:

| Element | What it connects | What it does (in plain language) |

|---|---|---|

| PV inverter / PV system | Solar → building | Produces electricity during the day |

| PCS (bidirectional inverter) | AC ↔ DC | Moves power to/from the battery |

| Battery + BMS | DC side | Stores energy safely |

| EMS (software) | Data + controls | Decides when to charge/discharge for savings |

| Metering | Grid + loads | Measures consumption and peaks for optimization |

This is why commercial battery storage is not just “a big battery”—it’s a complete system designed to control energy flows.

Applications of a business ESS/BESS (what companies actually use it for)

Most businesses invest in an energy storage system for one or more of these three value streams.

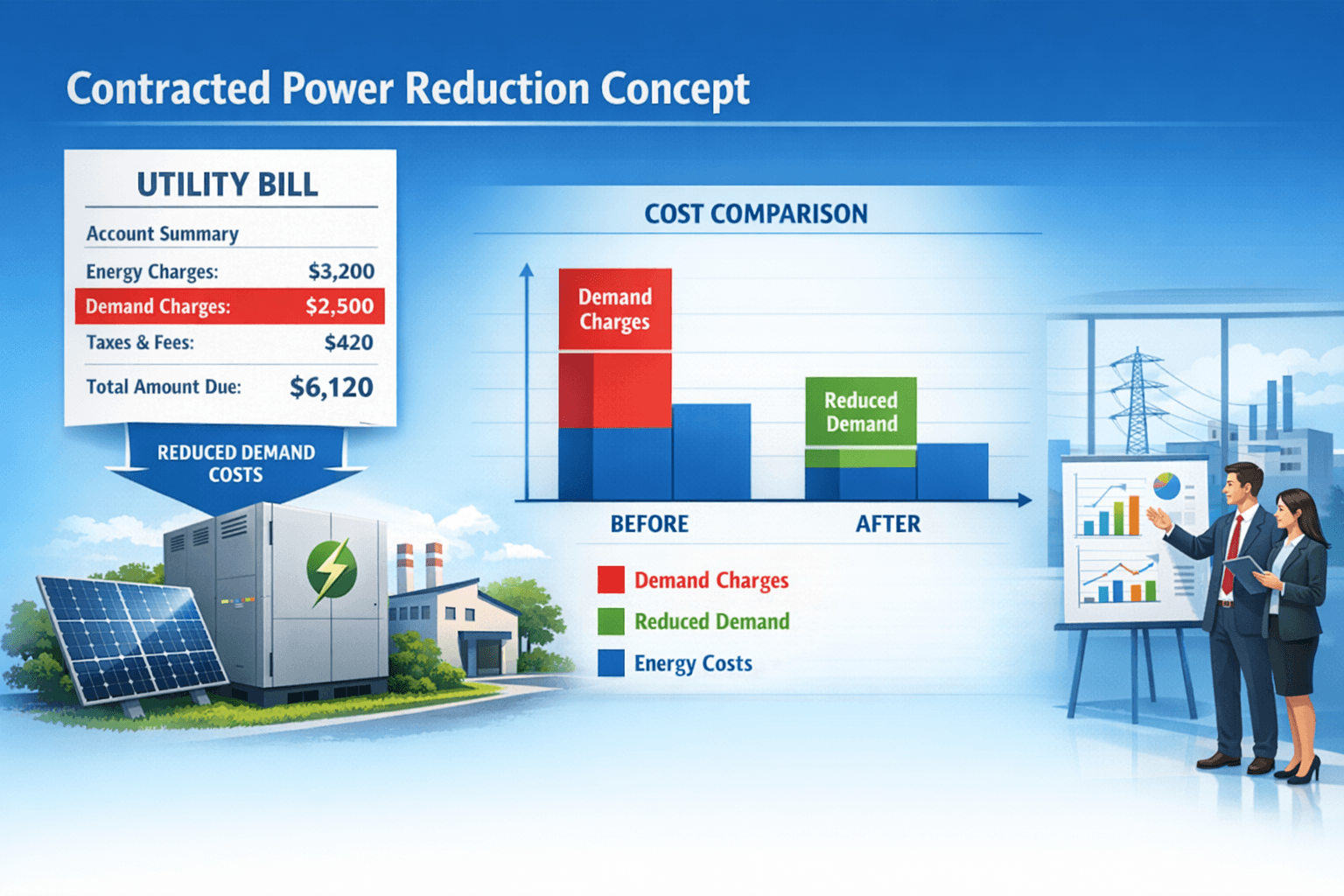

Peak shaving (cutting demand peaks)

Peak shaving means using the battery to reduce your highest short-term power draws (your “peaks”). Many commercial tariffs include charges or penalties that increase strongly with peak demand.

How it works operationally:

- Your load spikes (e.g., machines start, HVAC ramps, compressors kick in)

- EMS detects the spike (or predicts it) and discharges the battery

- The grid “sees” a flatter load profile

Result: lower peak-related costs and often a more stable operation. Peak-time management is a core rationale for ESS in many educational resources (c3controls, Exro).

PV integration (more self-consumption, less curtailment)

If you have solar PV, storage helps you use more of your own energy:

- store surplus PV generation midday

- use it later (evening shifts, after work hours, early morning start-ups)

Instead of exporting when prices are low (or when export is limited by rules), you turn intermittent PV into dispatchable on-site energy. Many commercial BESS guides list PV synergy as a primary application (Vertiv).

Dynamic pricing / time-of-use arbitrage

In variable pricing models, the battery can:

- charge when electricity is cheaper (off-peak)

- discharge when electricity is more expensive (peak hours)

This is often called arbitrage. It’s a straightforward concept, but the real-world success depends on:

- your tariff structure

- your consumption profile

- battery efficiency and cycling limits

- the quality of the dispatch algorithm (EMS)

Commercial resources commonly describe time shifting/arbitrage as a key BESS use case (EPRI, Exro).

Benefits of commercial battery storage (in business language)

Here’s what a well-designed ESS/BESS typically delivers for a facility:

- Lower electricity bills through peak shaving and time shifting

- Better use of PV (higher self-consumption, less wasted solar production)

- More predictable energy costs (less exposure to price spikes)

- Improved operational resilience (depending on design: backup/UPS-like behavior)

- A platform for future flexibility (e.g., adding more PV, EV charging, or grid services)

The key is to size and control the system for your load profile—because the same battery can perform very differently across two sites.

How to size a business energy storage system (quick orientation)

Sizing is where many projects succeed or fail. You don’t need to become an engineer, but you should understand the two basic parameters:

- Power (kW): how big a peak you want to shave (or how much load you want to support)

- Energy (kWh): how long you want to sustain that discharge (or how much cheap energy you want to shift)

A practical way to think about it:

| Your primary goal | Typically prioritizes | Simple rule of thumb |

|---|---|---|

| Peak shaving | kW (power) | Size kW to cover the “top” of your peaks |

| PV self-consumption | kWh (energy) | Size kWh to capture typical PV surplus |

| Dynamic pricing | both | Needs kWh for shifting and kW for high-price hours |

For accurate sizing, you need interval data (15-minute or hourly) and your tariff rules. That’s exactly why tools and automated analysis are helpful.

What data do you need to calculate ROI?

To accurately calculate energy storage savings, you need:

- Energy consumption profile (hourly or 15-minute intervals) or invoices + interval data

- Tariff / pricing model (fixed vs dynamic)

- Contracted power / peak demand information

- Existing PV installation details (kWp, production, self-consumption)

Who is a business ESS/BESS for?

A commercial battery storage system is usually a strong fit if you have at least one of these:

- High peak demand relative to average load (peaky consumption)

- Dynamic pricing / time-of-use tariffs or exposure to price spikes

- Solar PV with surplus generation (or plans to install PV)

- Operational sensitivity to power events (voltage dips, downtime costs)

- Growth plans (new production lines, expanded HVAC, EV chargers)

Typical facility types:

- factories and workshops

- warehouses and logistics centers

- office buildings and retail sites with significant HVAC

- mixed-use commercial properties

If you’re unsure, the fastest starting point is to simulate savings from your meter data.

Why AIESS? (automation matters more than most people think)

Why AIESS?

AIESS energy storage systems stand out with:

- AI Control - automatic charge/discharge scheduling

- Forecasts - energy prices, weather, load predictions

- 24/7 Monitoring - savings reports and continuous optimization

Because in real facilities, “set-and-forget” isn’t a luxury—it’s what makes ESS profitable without adding workload to your team.

FAQ (Frequently Asked Questions)

-

What is the difference between ESS and BESS?

ESS is the broad term (any energy storage technology). BESS specifically means a battery energy storage system—typically what businesses buy today. -

How does a BESS work in a factory or warehouse?

It charges from PV or the grid, stores energy, and discharges during high-load or high-price periods. An EMS coordinates the process while the BMS protects the battery (EPRI, Vertiv). -

Will battery storage reduce my electricity bill even without solar?

Often yes—especially if you have demand peaks or a time-of-use/dynamic tariff. Savings come from peak shaving and arbitrage, not only from PV. -

What are PCS, EMS, and BMS in simple terms?

PCS is the power “converter” (AC↔DC), BMS is battery safety and balancing, EMS is the software that decides the operating strategy (EnergyToolbase, Power-Sonic). -

Is commercial battery storage safe?

Modern systems are designed with multiple layers of protection: BMS controls, thermal management, and electrical protection equipment. Proper design, installation, and monitoring are critical (Vertiv). -

What size battery do I need for peak shaving?

It depends on how high your peaks are (kW) and how long they last (kWh). A short, sharp peak can be solved with higher kW and moderate kWh; long peaks may need more energy capacity. -

Can an ESS/BESS work with my existing PV and electrical setup?

In most cases yes. Commercial BESS projects are commonly designed to integrate with existing PV and site distribution, but the exact topology depends on your grid connection and protection scheme. -

How do I estimate ROI quickly?

Use interval consumption data and your tariff model to simulate peak shaving and price arbitrage. AIESS ROI calculator →

Summary

A business energy storage system (ESS/BESS) is a commercial battery solution that stores electricity and releases it strategically to reduce costs and improve energy control. The core building blocks are the battery, BMS (safety and longevity), PCS (bidirectional conversion), and EMS (optimization). In real business use, ESS/BESS creates value mainly through peak shaving, PV self-consumption, and dynamic pricing arbitrage—and the quality of the control strategy often determines how fast the system pays back.

Next steps

If you want to see whether an ESS/BESS makes financial sense for your facility:

- Estimate savings and payback based on your tariff and load profile: Check potential ROI →

- Explore implementation options and what “100% automatic” control looks like: AIESS offer →

Related articles

- Energy storage for peak shaving: how it reduces demand charges

- Commercial battery storage ROI: what drives payback time?

- PV + battery storage for businesses: increase self-consumption

Sources and References

Article based on data from:

- EPRI. “Energy Storage 101.”

https://storagewiki.epri.com/index.php/Energy_Storage_101 - Vertiv. “What is a battery energy storage system (BESS)?”

https://www.vertiv.com/en-us/about/news-and-insights/articles/educational-articles/what-is-a-battery-energy-storage-system-bess/ - EnergyToolbase. “The Primary Components of an Energy Storage System.”

https://www.energytoolbase.com/blog/energy-storage/components-of-an-energy-storage-system/ - Power-Sonic. “Battery Energy Storage System Components.”

https://www.power-sonic.com/battery-energy-storage-system-components/ - EcoFlow. “Battery Energy Storage System: Definition, Components & Types.”

https://www.ecoflow.com/za/blog/battery-energy-storage-system - c3controls. “Understanding Energy Storage Systems (ESS).”

https://www.c3controls.com/white-paper/understanding-energy-storage-systems - Exro Technologies. “Commercial Battery Storage System FAQs.”

https://www.exro.com/industry-insights/frequently-asked-questions-about-commercial-battery-storage-systems

Last updated: January 4, 2026