Peak shaving explained: how ESS reduces bills and peak demand

Peak shaving with commercial ESS reduces peak demand charges by shaving load spikes in manufacturing and service facilities. Check savings potential.

Peak shaving explained: how ESS reduces bills and peak demand

Peak shaving is a way to reduce your electricity bill by using an energy storage system (ESS/BESS) to cut (“shave”) short power spikes so your facility draws less maximum power from the grid. This article is for manufacturing facility managers, energy managers, and production directors who want predictable savings without changing how production runs. You’ll learn how peak shaving works in practice, when it delivers the biggest savings, and what data you need to estimate ROI in minutes.

What is peak shaving?

Peak shaving means reducing your site’s highest measured grid demand during a billing period—typically the maximum average power over a short interval such as 15 minutes—so you pay lower peak demand charges and, in some markets, avoid higher capacity fees or tariff bands (Next Kraftwerke, Power Sonic).

A simple way to think about it:

- Energy (kWh) is how much electricity you use overall.

- Demand / peak demand (kW) is how fast you consume electricity at the worst moment.

- Many commercial and industrial tariffs include a cost component tied to that worst moment. Peak shaving targets that component.

Peak shaving is especially valuable in facilities where peaks are:

- short but frequent (equipment start-ups, compressed air, HVAC ramps),

- hard to shift (continuous production),

- expensive (demand charges or capacity tariffs are high).

How does peak shaving work with a commercial ESS?

An ESS for peak shaving acts like a buffer between your loads and the grid: it charges when demand is low (or when solar generation is high), and discharges when your site demand approaches a predefined threshold—so the grid “sees” a lower peak.

The basic mechanism (step-by-step)

-

Measurement (real time)

The ESS controller continuously reads site power at the grid connection point (and often key sub-meters). -

Prediction (minutes to hours ahead)

Using historical patterns and current conditions, the controller forecasts whether you’re about to exceed a peak limit (e.g., shift change, batch start, chiller ramp). Advanced approaches use optimization and predictive control rather than fixed setpoints (Sandia National Laboratories). -

Charge when it’s “cheap” or “available”

- Off-peak hours (time-of-use tariffs)

- Low-load periods at night

- Midday PV surplus (if you have solar)

-

Discharge when you approach the threshold

The battery discharges through an inverter to support your load so grid import stays under the target. -

Respect battery limits and safety

Control logic protects:- state of charge (SoC) min/max,

- temperature,

- power limits,

- cycle strategy (avoid unnecessary cycling).

This is why peak shaving is not only “a battery”, but a battery + inverter + control software system (gridX).

Two common control strategies (and why they matter)

| Strategy | How it works | Pros | Cons | Best for |

|---|---|---|---|---|

| Fixed threshold (“shave level”) | Discharge whenever grid import exceeds a set kW value | Simple, predictable | Can run out of energy too early; may miss late-day peaks | Sites with stable, repeatable peaks |

| Predictive/optimized control | Forecasts peaks and allocates battery energy across the day | Better use of capacity; adapts to changing days | Needs good data and smarter controller | Sites with variable loads, multiple peaks, PV, dynamic prices |

Research and industry practice emphasize that better forecasting and optimization improves results, because the “right” shave level depends on daily patterns, not just a single number (Sandia National Laboratories, Exactus Energy).

Peak shaving vs load shifting: key difference for manufacturing

Peak shaving does not require you to change production schedules. Instead of moving loads, you keep operations unchanged and let the battery handle the peaks. That’s why it fits:

- continuous lines,

- quality-sensitive processes,

- plants where downtime costs more than electricity.

Applications of peak shaving (real operational use cases)

Peak shaving is a practical tool across many commercial and industrial settings, but it shines where demand peaks are sharp and expensive.

Manufacturing: start-up spikes and batch peaks

Common peak drivers:

- large motor starts (pumps, fans, mills),

- welding lines,

- compressors and compressed air systems,

- ovens and thermal processes cycling,

- simultaneous start-ups after breaks.

If these spikes push your measured demand to a new monthly maximum, you pay for it all month (depending on tariff structure). A properly sized BESS can cover those spikes for minutes to an hour without touching production.

Service facilities: HVAC, refrigeration, and building peaks

Common peak drivers:

- afternoon cooling load,

- heat pumps or electric boilers starting,

- refrigeration racks cycling,

- elevators and building services overlapping with tenant usage.

Many buildings have predictable daily peaks—ideal for automated peak shaving with minimal operational involvement (Power Sonic).

Data centers and critical infrastructure

Data centers face:

- high, steady base load,

- expensive capacity-related charges,

- strict uptime requirements.

Peak shaving can complement UPS strategies where regulations and design allow. Industry examples show meaningful grid draw reduction during peaks when storage is deployed at scale (Exactus Energy).

EV charging hubs and fleet depots

Fast chargers can create extremely high short-duration peaks. Peak shaving helps:

- avoid costly grid upgrades,

- keep demand charges under control,

- enable more chargers on the same connection (Power Sonic).

Benefits of peak shaving (what you actually gain)

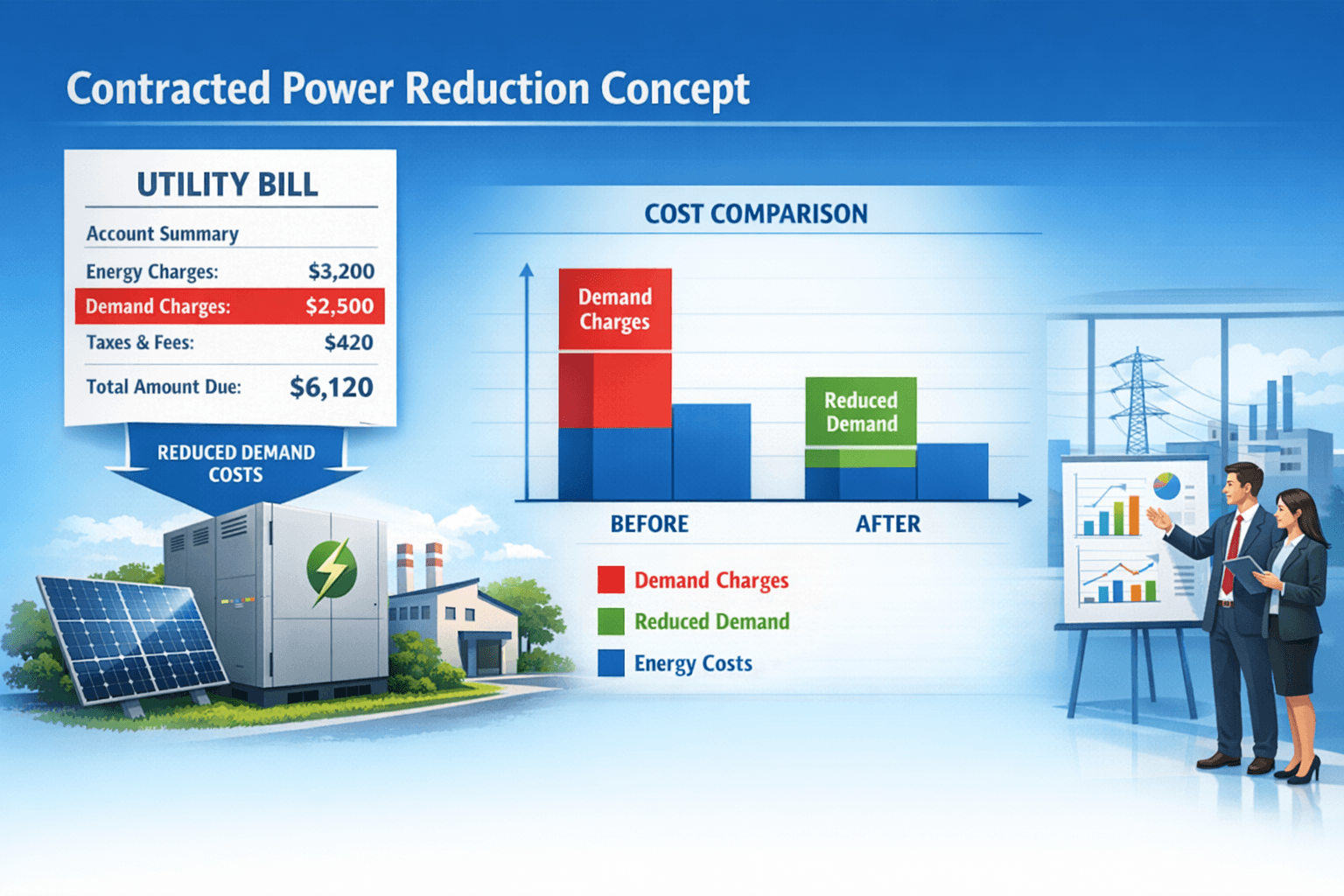

Peak shaving is often sold as “lower bills”, but it’s important to understand which part of the bill and why the savings can be substantial.

1) Lower peak demand charges / capacity fees

The main win is reducing the maximum billed demand (kW) so you pay less for that tariff component (Next Kraftwerke, gridX).

2) More predictable energy costs (less “penalty” from rare events)

Many facilities have “rare” peaks:

- one maintenance day,

- one hot week,

- one unusual production batch.

But demand billing can make that rare event expensive for the entire period. Peak shaving acts like insurance against those outliers.

3) Better use of on-site solar (if you have PV)

When PV output is high but your site load is lower, charging the battery can:

- reduce export (where export value is low),

- store energy for later peaks (afternoon production, HVAC),

- increase self-consumption.

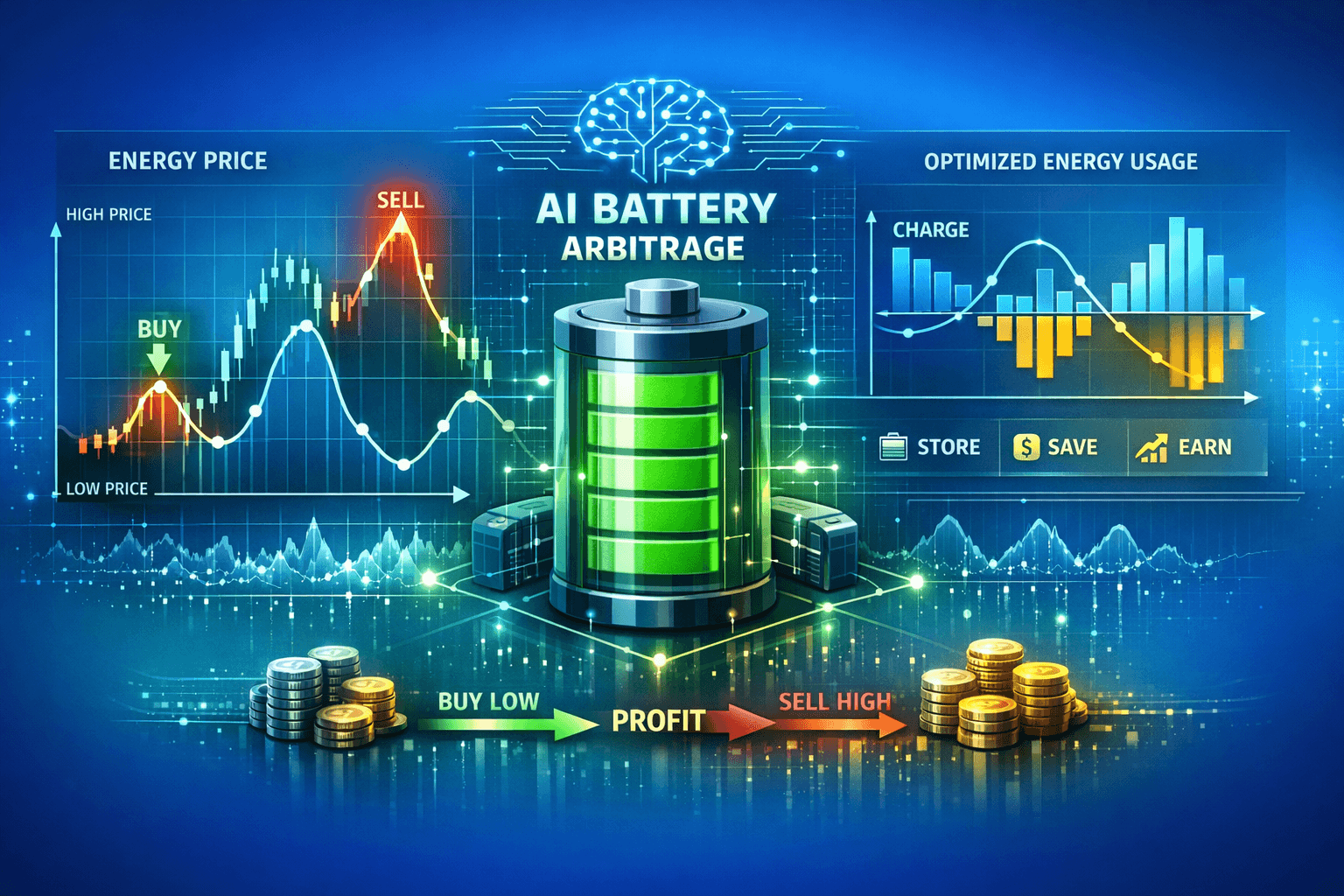

4) Optional stacking: peak shaving + price arbitrage + demand response

If your market/tariff allows, a smart ESS can do more than peak shaving:

- charge when prices are low, discharge when high (arbitrage),

- participate in demand response programs (incentives for reducing load at critical times).

Stacking is where software becomes decisive: you want to prioritize peak-demand reduction without “wasting” capacity on low-value cycles (Sandia National Laboratories, gridX).

When does peak shaving deliver the biggest savings?

Peak shaving can be a quick-payback measure—but only under the right conditions. Based on industry guidance and control research, the biggest savings typically show up when demand-related charges are high and peaks are spiky (Exactus Energy, Sandia National Laboratories).

High-impact scenarios (quick checklist)

Peak shaving tends to work best when you have 3+ of these:

- You pay a separate line item for max demand (kW) or capacity-related charges.

- Your load has sharp peaks (start-ups, batch processes, HVAC ramps).

- Peaks occur frequently enough to justify cycling, but are short enough for a battery to cover (minutes to ~2 hours).

- You can define a clear target (e.g., “never exceed 450 kW”).

- You have PV and midday surplus that can charge the battery.

- Your operations are inflexible (you cannot simply reschedule loads).

Situations where peak shaving is often weaker

- You have a very flat load profile with no pronounced peaks.

- Demand charges are minimal or not present in your tariff.

- Peaks last many hours every day (then the required energy capacity becomes large).

- You already manage peaks successfully through process scheduling or automated load shedding.

A practical “peak shape” rule of thumb

Before even talking to vendors, look at your interval data and ask:

-

Is my monthly maximum demand driven by 10–60 minute events?

Peak shaving is usually a great fit. -

Is my maximum driven by 3–6 hour plateaus?

You may still benefit, but you’ll need more kWh capacity, and economics must be checked carefully.

Example: how peak shaving changes a load profile

Here’s a simplified daily profile (illustrative):

| Time | Load without ESS (kW) | ESS action | Grid load with peak shaving (kW) |

|---|---|---|---|

| 07:00–09:00 | 320 | Charge (low demand) | 360 |

| 09:00–10:00 | 520 (equipment start) | Discharge | 450 |

| 10:00–14:00 | 430 | Idle/charge from PV surplus | 430 |

| 14:00–15:00 | 500 (batch peak) | Discharge | 450 |

| 15:00–18:00 | 410 | Idle | 410 |

Two key insights:

- The grid “sees” 450 kW max instead of 520 kW.

- The battery doesn’t need to run all day—just during the peaks.

How to size an ESS for peak demand reduction (without overcomplicating it)

Peak shaving sizing is about matching power (kW) to the size of your peaks and energy (kWh) to their duration.

Step 1: Determine your target demand limit

You typically set a “shave level” below:

- your contracted power,

- your tariff threshold,

- or your historical max demand minus a safety margin.

Example: if you hit 600 kW peaks and want to cap at 520 kW, you need up to ~80 kW of discharge power during those events.

Step 2: Estimate how long peaks last

If that 80 kW is needed for 30 minutes, the energy required is:

- 80 kW × 0.5 h = 40 kWh (plus losses and buffer)

Real sites usually have multiple peaks; you size for:

- the worst peak,

- plus enough energy to cover the typical daily pattern.

Step 3: Don’t forget operational constraints

Real-world usable energy is less than nameplate because you keep safety SoC buffers and account for efficiency. Control approaches discussed in peak shaving literature emphasize respecting constraints to avoid early depletion and to allocate energy across the day (Sandia National Laboratories).

A quick sizing cheat sheet (rule-of-thumb)

| What you see in interval data | What you likely need | Typical outcome |

|---|---|---|

| Short spikes (5–15 min) | Higher kW, modest kWh | Big demand reduction with small energy capacity |

| Medium peaks (15–60 min) | Balanced kW and kWh | Strong savings, common in manufacturing |

| Long peaks (1–4 h) | High kWh | Feasible, but economics depends on demand charges |

What data do you need to calculate ROI?

To accurately calculate energy storage savings, you need:

- Energy consumption profile (hourly or 15-minute intervals) or invoices + interval data

- Tariff / pricing model (fixed vs dynamic)

- Contracted power / peak demand information

- Existing PV installation details (kWp, production, self-consumption)

What makes peak shaving “automatic” (and why AI control matters)

A peak shaving ESS can be run with simple fixed settings, but facilities rarely stay perfectly predictable:

- production changes,

- seasons change HVAC load,

- new machines are added,

- PV output varies with weather.

This is where advanced control helps: it can forecast peaks and decide when to charge and discharge so you don’t drain the battery too early or waste capacity on the wrong hours (Sandia National Laboratories, gridX).

Why AIESS?

AIESS energy storage systems stand out with:

- AI Control - automatic charge/discharge scheduling

- Forecasts - energy prices, weather, load predictions

- 24/7 Monitoring - savings reports and continuous optimization

Common misconceptions (and how to avoid expensive mistakes)

“Peak shaving will cut my total kWh a lot”

Not necessarily. Peak shaving mainly cuts kW-based charges, not total energy use. You may still reduce some kWh costs if you also do price arbitrage or better PV self-consumption.

“Any battery will do”

Hardware matters, but control and integration (meters, inverter limits, safety constraints) determine whether the battery actually hits your peak targets reliably (Exactus Energy, Sandia National Laboratories).

“We should just set the lowest shave level possible”

If you set the limit too low, you may:

- cycle unnecessarily,

- deplete early,

- miss late peaks that drive billing maximums.

Optimized control aims to use battery energy where it changes the billed maximum most effectively.

Who is peak shaving for?

Peak shaving is a strong fit for:

- Manufacturing plants with shift-based peaks, motor starts, batch processes, compressed air, and high contracted power.

- Warehouses and logistics with overlapping HVAC + charging equipment + operational peaks.

- Commercial buildings where HVAC drives predictable peaks.

- Data centers and mission-critical sites that need demand control without operational disruption.

- EV charging depots where grid connection limits and demand charges are major cost drivers.

If you’re an energy manager or facility manager, peak shaving is one of the few measures that can deliver savings without touching production schedules—when tariffs and load profile support it.

FAQ (Frequently Asked Questions)

-

What is the difference between peak shaving and load shedding?

Peak shaving reduces grid peaks by supplying part of the load from an ESS. Load shedding reduces peaks by temporarily turning off or limiting equipment. Peak shaving is usually less disruptive (Next Kraftwerke). -

Does peak shaving work if my peaks are unpredictable?

It can, but you’ll benefit more from predictive control that uses interval data and adapts to changes, rather than a fixed threshold approach (Sandia National Laboratories). -

How much can a commercial ESS reduce peak demand?

Results depend on your load profile and system size. Industry examples and guides report meaningful reductions when storage is properly sized and controlled (Exactus Energy, Power Sonic). -

Will peak shaving shorten battery life?

Any cycling affects battery life, but peak shaving typically involves controlled, partial cycles. A good EMS keeps operation within safe SoC and temperature limits, improving longevity in real use. -

Do I need solar PV for peak shaving?

No. PV can improve economics by providing low-cost energy for charging, but peak shaving also works with grid charging—especially with time-of-use tariffs. -

How do I know if demand charges are the main driver of my bill?

Check invoices for line items like “demand charge”, “capacity charge”, “max kW”, or tariff bands based on peak power. If that component is significant, peak shaving is worth evaluating. -

Can peak shaving help avoid grid connection upgrades?

Often yes—especially for EV charging or expanding production—because limiting maximum import can keep you under connection capacity and reduce upgrade needs (Power Sonic).

Summary

Peak shaving uses an ESS/BESS to reduce your facility’s maximum grid demand during short high-load periods, cutting peak demand charges without changing production. It delivers the biggest savings where demand-related fees are high and peaks are short, frequent, and hard to shift—typical in manufacturing and many service facilities. The right results depend on accurate interval data and a controller that can forecast and allocate battery capacity across the day.

Next steps

- Estimate your savings potential based on your tariff and interval data: Check savings potential →

- If you want a practical plan for your site (sizing, integration with PV, operational constraints), explore our solutions: AIESS offer →

Related articles

- What is an ESS (energy storage system) and how does it work?

- Energy storage ROI: what drives payback in commercial & industrial sites

- PV self-consumption with battery storage: practical guide for businesses

- Demand response for businesses: how batteries unlock additional revenue

Sources and References

Article based on data from:

- Power Sonic (2026). “The Power of Peak Shaving: A Complete Guide.”

https://www.power-sonic.com/the-power-of-peak-shaving-a-complete-guide/ - Exactus Energy (2025). “What Is Peak Shaving Energy Storage? Benefits & Uses.”

https://www.exactusenergy.com/blog/what-is-peak-shaving-energy-storage - Sandia National Laboratories (2013, updated 2026). “Peak Shaving Control Method for Energy Storage” (PDF).

https://www.sandia.gov/ess-ssl/EESAT/2013_papers/Peak_Shaving_Control_Method_for_Energy_Storage.pdf - Next Kraftwerke (2019, updated 2026). “What does Peak shaving mean?”

https://www.next-kraftwerke.com/knowledge/what-is-peak-shaving - gridX (2025, updated 2026). “Peak shaving: Everything you need to know.”

https://www.gridx.ai/knowledge/peak-shaving - EticaAG (2025, updated 2026). “Peak Shaving with Battery Energy Storage Systems.”

https://eticaag.com/peak-shaving-with-battery-energy-storage-systems/

Last updated: January 19, 2026